Sustainability is at the core of our business. We have undertaken various sustainability initiatives to enhance socio-economic value for all our stakeholders while minimising the environmental footprint of our operations.

At Jubilant Ingrevia Limited, we aim to manufacture products for our customers through optimized utilisation of resources to minimise the effect on the environment. We also have state-of-the-art environment protection equipment at all our manufacturing facilities. We strive to reduce our carbon footprint through the several energy consumption reduction initiatives and by the use of different renewable energy sources.

Climate Change

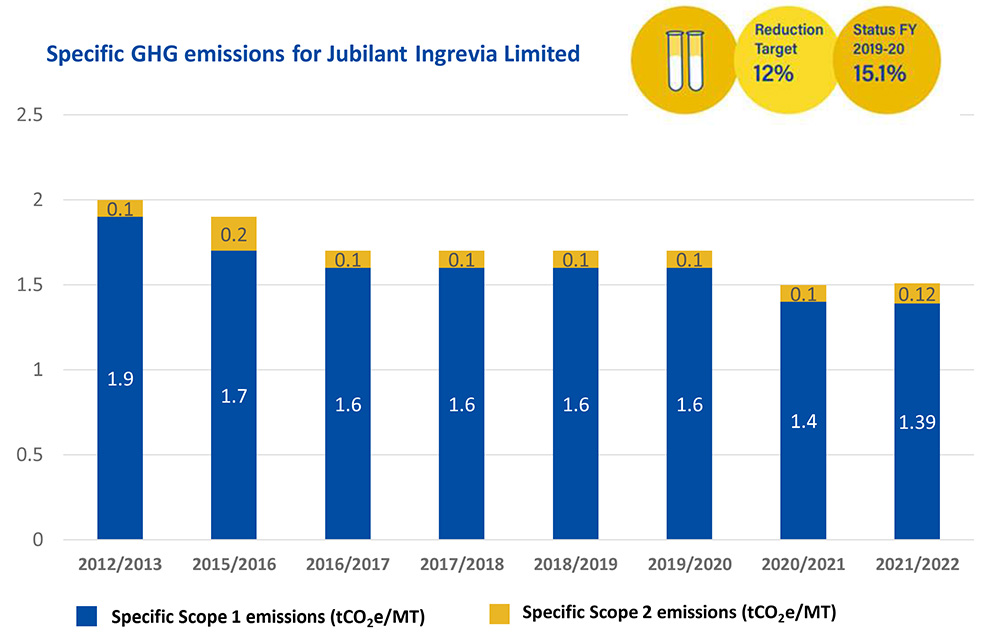

Jubilant understands the risks Climate Change can bring to our businesses with respect to the depletion of natural resources like water and agro-based raw materials like molasses. We believe that the global emission of Greenhouse Gases (GHG) is the major contributor for Climate Change. As a responsible corporate, to address climate change, we reduced specific GHG emissions from our facilities year on year, by continuously working on reduction in energy consumption, waste generation, increase in renewable energy share and enhancing the carbon sinks by planting more trees.

This year, we have completed third party assurance of our PCF (Product Carbon Footprint) Report of 28 products covering 4 manufacturing sites, namely Gajraula, Bharuch, Nira & Savli/ Samlaya. The study was conducted using the cradle-to-gate LCA (Life Cycle Assessment) approach and following ISO 14067:2018 standard. The PCF values are being assured by a Ernst Young Associates & LLP. These PCF values will help our customers to monitor scope 3 emissions and design their net zero strategy.

Enclosed is our third party assured PCF report along with assurance statement: web link

Sustainable Raw Materials

To remain cost-competitive, we always practice the efficient use of quality material in our processes. Our Company utilises molasses as its key raw material (a by-product from the sugar industries). As per the life cycle-based carbon footprint study, it was evident that Pyridine manufactured by Jubilant through Ethanol (manufactured from molasses) route has a much lesser carbon footprint than similar products which are manufactured through conventional petro route.

Molasses (a by-product from the sugar industries), press mud and corn cob are renewable in nature and constitute 45.5% of the total major raw material consumption.

Water

Being a Life Sciences company, we are dependent on water for many of our manufacturing processes. At the same time, we also deeply understand how critical this natural resource is to human life and ecosystems.

We continuously work to recycle back, usable water from the effluents after treatment in order to reduce fresh-water consumption. Most of our Indian manufacturing facilities are zero liquid discharge.

Year on year, we reduced specific fresh-water consumption from our facilities by continuously monitoring, reviewing and optimising water consumption through process modifications and adoption of new technologies.

Circular Economy

At Jubilant Ingrevia Limited, we aim to address waste management through a circular economy. We envisage creating an economic system aimed at eliminating waste and the continual use of resources. We believe in reuse, sharing, repair, refurbishment, remanufacturing and recycling to create a closed-loop system, minimising the use of resource inputs and the creation of waste, pollution and carbon emissions. To address the above we have undertaken few initiatives:

-

Utilisation of Fly-ash for bricks, cement, road, construction etc.

-

Converting waste from distillery into Bio-compost which helps farmers as low-cost nutrient supplement for agriculture.

-

Recycle and Reuse of suitable waste through authorised third party

-

Co-processing of specific waste at a cement kiln

-

Steam generation through incineration of a specific category of hazardous waste

Recognitions

Our sustainability efforts have been recognised and appreciated at many national and international forums organised by institutions like the Confederation of Indian Industry (CII), Federation of Indian Chambers of Commerce and Industry (FICCI), Indian Chemical Council (ICC) etc. The company also received an appreciation letter from GRI for our contribution towards strengthening sustainability reporting in India and our continued support of GRI’s mission and vision.

We attained an outstanding 95 percentile globally (CHM Chemicals) with 66/100 score in the S&P Global ESG Indices CSA 2022 (DJSI), signifying a substantial increase of 25% compared to last year's score. We take pride in attaining a GOLD Sustainability rating (score 68) in EcoVadis, placing us among the top 7% of global pharmaceutical companies. This achievement underscores our dedication to environmental, social, and governance factors. Additionally, we have received an impressive 'B' score band from CDP for 'Climate Change' and 'Water Security.' The company has moved from the 'C' (Awareness) band (last year's score) to the esteemed 'B' band, known as the 'Management' band. Additionally, we are fulfilling the reporting requirements of the Business Responsibility and Sustainability Reporting (BRSR) mandated by SEBI. You can find our BRSR report enclosed as part of our Annual Report for FY2023. In line with our commitment to climate mitigation and stakeholder demands, we have conducted a detailed Product Carbon Footprint (PCF) study of 28 products based on Life Cycle Assessment (LCA) following the ISO 14067:2018 standard. We have also engaged a third party to assure the Cradle to Gate LCA-based PCF of these 28 products.